Being teased by HotLimeLabs…

“Gaugler says he sees a few other technologies that have potential to add more value, helping overcome the tyranny of distance and cost to market.

They include converting slash to biochar for soil remediation, a process that can also produce syn-gas for powering the biochar plant, and biochemicals that are a viable alternative to hydrocarbon-sourced chemicals.

………….

Other work in Northland includes a study on the value of biochar and its value in soil remediation.”

I’ve been trying to find out more about this initiative, thinking that BNNZ might be able to help or collaborate. I posted to the BNNZ FB page on some earlier media coverage and tried to engage via Eastern Institute of Technology but not much success so far.

It would be great to see BNNZ connected & collaborating on technical aspects of biochar production from beached biomass.

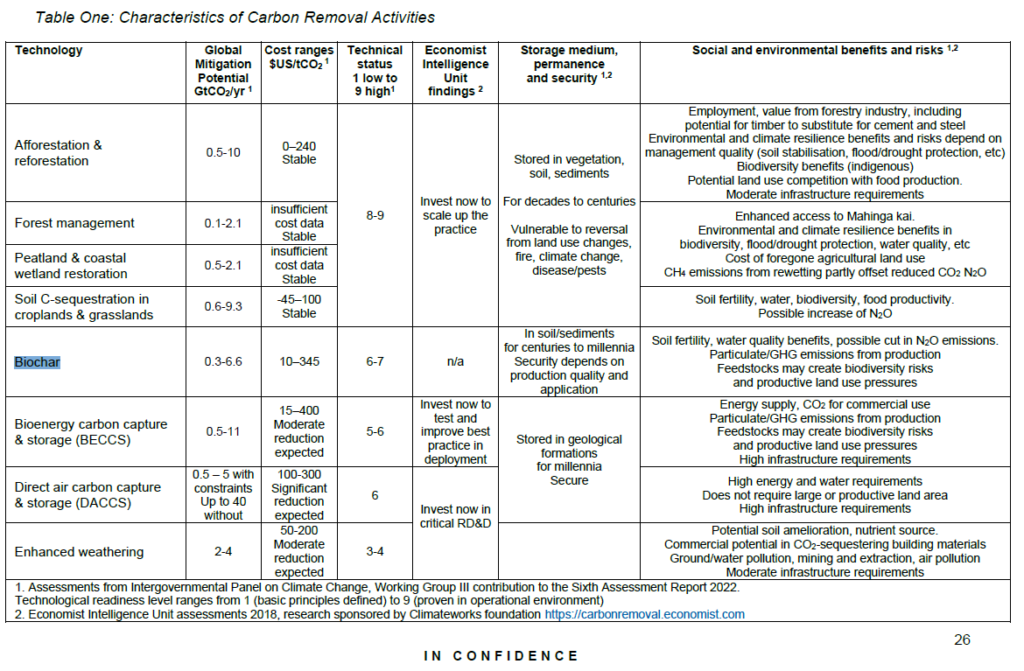

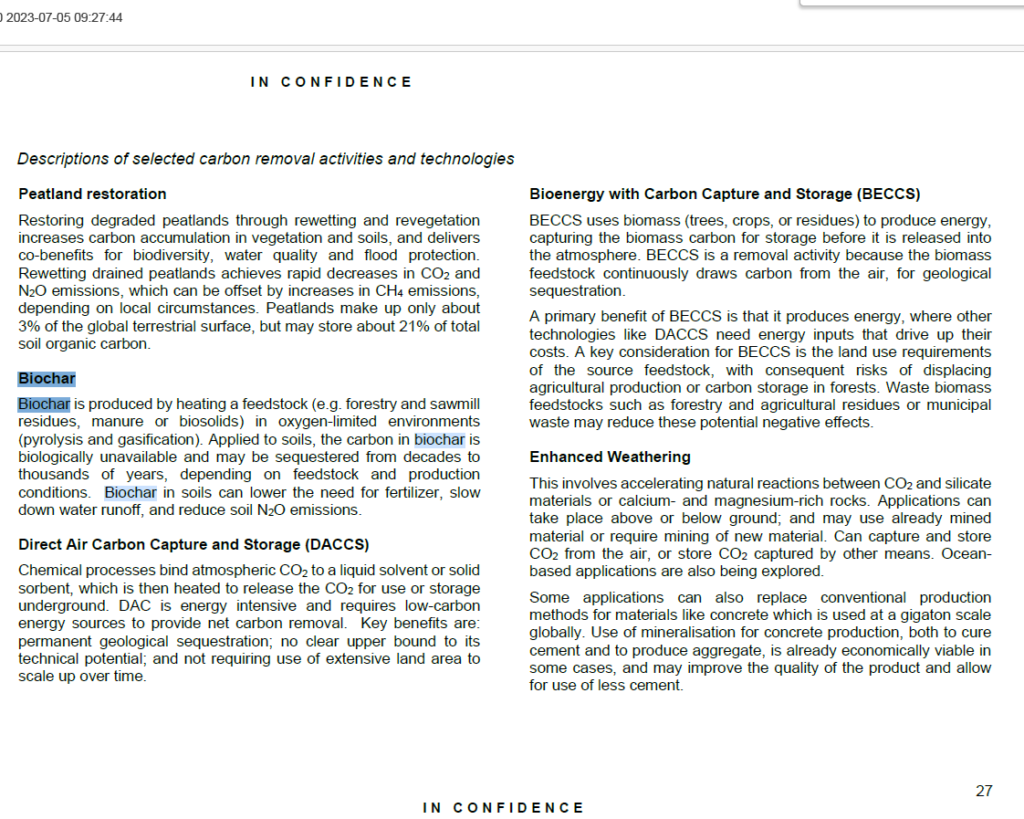

Developing a Carbon Removals Strategy

“New Zealand currently relies on continually expanding forests for the carbon removals needed to meet emissions budgets and the Nationally Determined Contribution under the Paris Agreement. A broader portfolio of activities is needed to sequester atmospheric CO2. This paper seeks agreement to develop a Carbon Removals Strategy.“

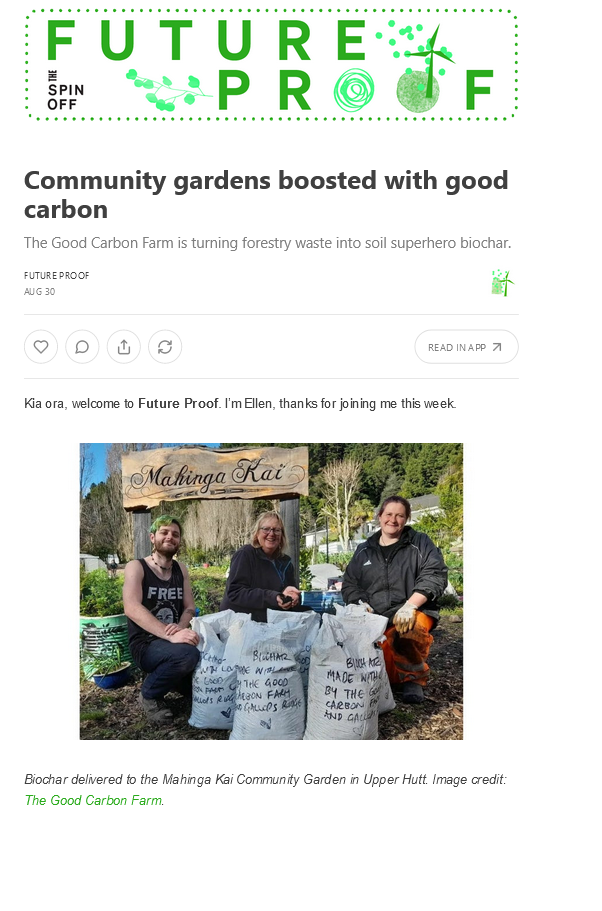

Kapiti Coast District Council provides ‘climate action grants’ to two biochar community projects (above & below)

It is great to see Future Proof continuing to show interest in biochar. Hoping to see Bernard &Co. chatting about it on The Hoon soon.